When it comes to joining pieces of metal together, the mig welder is the essential piece of equipment. It is necessary to remember that mig welder capacity must be appropriate for the job at hand. This is one of the most important things to keep in mind. To have a decent output, it is vital to ensure you can complete the required duties with the appropriate settings. Therefore, paying attention to this detail is vital.

It’s not always easy to determine which one is the best mig welder that fits your needs. First, you must consider various things. Additionally, since there is such a vast selection of mig welders, you may decide which one to buy.

As you continue to read this article, you will be provided with information that will direct you toward the best mig welder that best suits your needs.

The size of the mig welder you need is determined by several criteria, including the machine’s power output, the kind of material being welded, the thickness of the material being welded, and the amount of expertise you have. The work you can do with your mig welder is ultimately determined by combining all of these factors.

A comprehensive explanation of each component is provided in the following paragraphs:

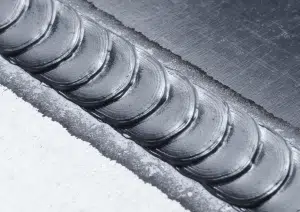

Welders that use mig technology perform very well when working with steel, stainless steel, and aluminum alloys. All three types of material may be welded with a single piece of equipment. However, it is recommended that you invest in a welder that can handle several processes. However, given you are asking this question, I will presume that you want to weld mild steel since that is what you are requesting information on. After that, if you want to learn how to weld aluminum and stainless steel, I suggest getting some TIG welding experience.

Alternatively, you may get some experience with steel first before going on to more unusual alloys. Welders that use the mig process can join standard steel since this is the material they were built on in most cases.

The amount of electricity that is being supplied is the second essential component. A modest power output such as 120V is provided in households, while a larger voltage of 240V or more is offered in industrial settings and other locations. If you don’t already have a 240-volt outlet, you probably can buy one if you have some cash on hand and look into it.

You must choose the size of the mig welder you will use based on the space in which you will be working and the number of outlets you will have accessible. For example, if you want to conduct some welding at home with sheet metal, all you need is a mig welder that operates on 120 volts.

Higher power output is necessary from the machine to complete a welding task on an industrial scale. If you wish to join the 240-volt network or weld thicker materials, investing in a device that can accept inputs of both 120 and 240 volts would be a good idea. However, in other situations, it might not be cost-effective to do so.

A few distinct kinds of power inputs and outputs may be found in a selection of mig welders. Some of them are also using alternating currents in their work. If you want to throw away money on ineffective equipment, they are a good option for you to consider. They may be purchased for a bit, and many individuals will list them for sale on platforms. The most positive aspect is that it is challenging, if not impossible, to weld with this inexpensive welder. You may get further information on the welding equipment that I believe is best suited for beginner welders.

Just take my word for it, but it is in your good to steer clear of AC and lower-end machines.

The depth or thickness of the material is still another crucial consideration. Do you need the creation of a sculpture made out of metal?

Is there a need for any fabrication on your motorcycle? Is there anything wrong with your steel fence that needs fixing? Alternatively, are you planning to improve your agricultural machinery?

Because of the variety of tasks that need to be completed, the material’s thickness will need to be adjusted accordingly. For this reason, a mig welder of the appropriate size can quickly deal with the material’s thickness. If you plan on welding for extended periods, it is recommended that you get a machine that is at least 30 percent more powerful.

It is unrealistic for a beginner to purchase heavy-duty equipment and invest several thousand dollars. Unfortunately, in most circumstances, this is not the case. It’s unlikely that you will ever use the machine’s full capabilities. For someone just starting, a basic mig welder that operates on 120 volts should be sufficient for practicing on sheet metal. Your motorcycle frames, sheet metals such as vehicle body panels, and other similar items are great for welding using this.

Investing in a highly effective mig welder is brilliant if you want to work with 3/8-inch mild steel. Because it is a substance of sufficient thickness, a power output of no less than 240 volts is essential. Invest in a tool that can generate at least 230 amps of power if your line of work requires you to deal with metals of a greater thickness and weight.

You can still use a mig welder even if your only power output is 120V if you buy one that operates on that voltage. Welding projects around the home and work with thin metals are best suited for this particular mig welder. Keep in mind that the power output of 120V can only do basic welding tasks, as this is an essential point to keep in mind. With this level of force, you won’t be able to weld any very thick or heavy materials successfully.

Practice, practice, and more are necessary for someone just starting! A machine with a high degree of tolerance for error is required for this task.

It should be pretty safe if you use a high-end mig welder as your welding machine of choice. The technology available today is of the highest quality, and while the price may be higher, you will get helpful safety features and other things that will make your life simpler if you start.

It is recommended that beginner welders begin their careers by focusing on welding thinner metals.

You may get your feet wet in the welding world by starting with simple projects around the home that demand less power output and less work.

Here’s a look at the top 10 MIG welders that are currently trending in the market, valued for their features, performance, and affordability:

Lincoln Electric 90iFC Flux Core

Hobart Handler 140 MIG Welder

Millermatic 211 MIG Welder

Forney Easy Weld 140 MP Multi-Process Welder

YESWELDER MIG-205DS Dual Voltage MIG Welder

Everlast Power i-MIG 140E

VIVOHOME MIG Welder 130

Lotos MIG175 175AMP MIG Welder

LOTOS MIG140

DEKOPRO 110/220V MMA Welder

Each of these welders has its own set of strengths tailored for different user needs, from household fixes to small-scale commercial projects.

You must base your decision to purchase a mig welder on the needs of your specific work. If you are a welder with a lot of expertise and professional background, you may be able to find work that involves more heavy-duty tasks. However, if you are new to the field of welding, it is recommended that you begin your journey with mig welders, which are more fundamental. You’ll eventually be able to move up to larger sizes if you keep at it. In addition, I strongly suggest you read this article, a buyer’s guide geared toward those just starting in the welding industry.

Read My Reviews On The 10 Best Mig Welder.

Disclaimer:

MigWelderCart.com provides content for informational purposes only and does not guarantee the accuracy or reliability of the items featured. We may earn commissions from qualifying purchases through the Amazon Associates Program and revenue from Google AdSense ads. Third-party vendors, including Google, use cookies to serve ads based on prior visits. Users can opt out of personalized ads via Google Ads Settings. All trademarks, brands, and images belong to their respective owners, and usage is at your own risk.